Tungsten Carbide Guhindura Indanganturo Shyiramo APMT1135 kuri amuninum / ibyuma bitagira umwanda / Ibyuma

Amakuru Yibanze

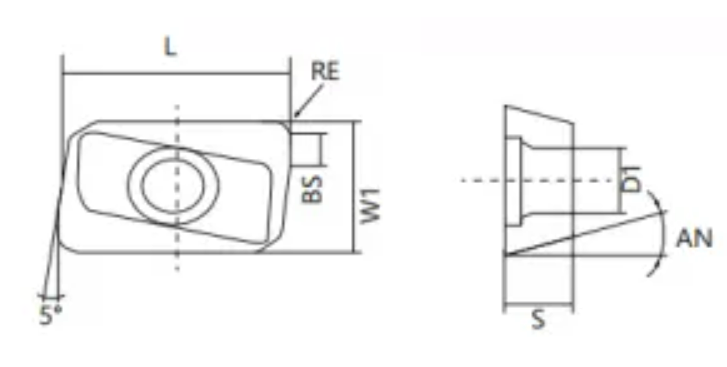

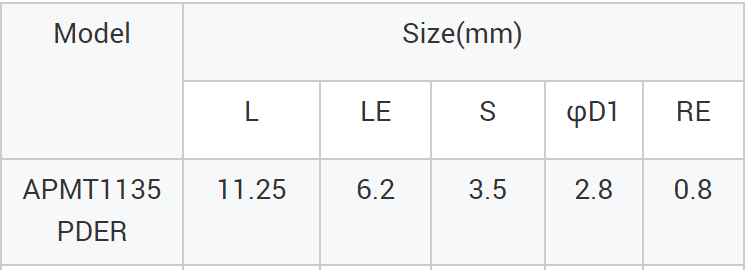

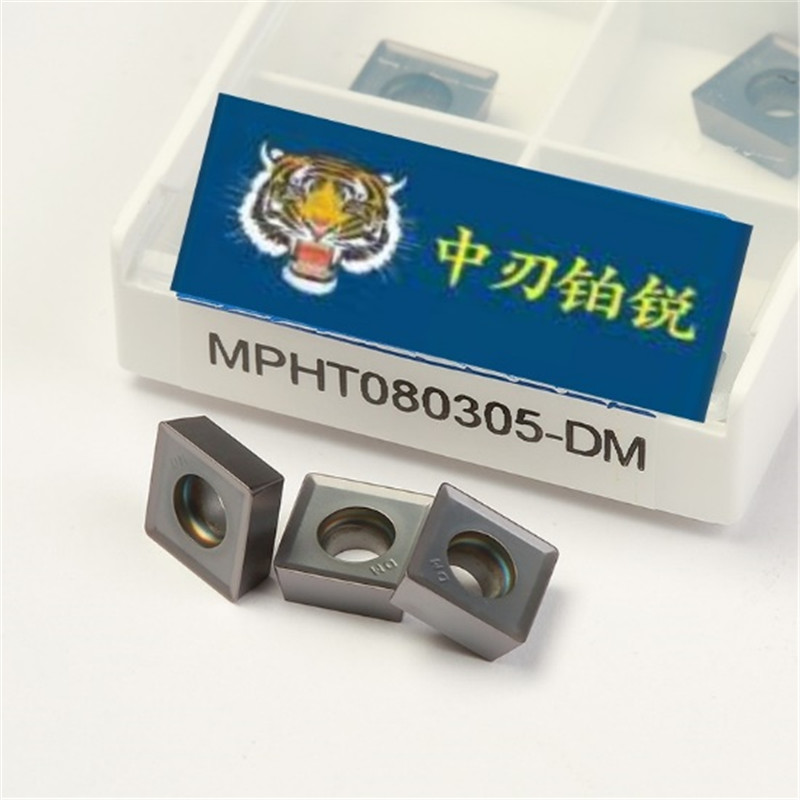

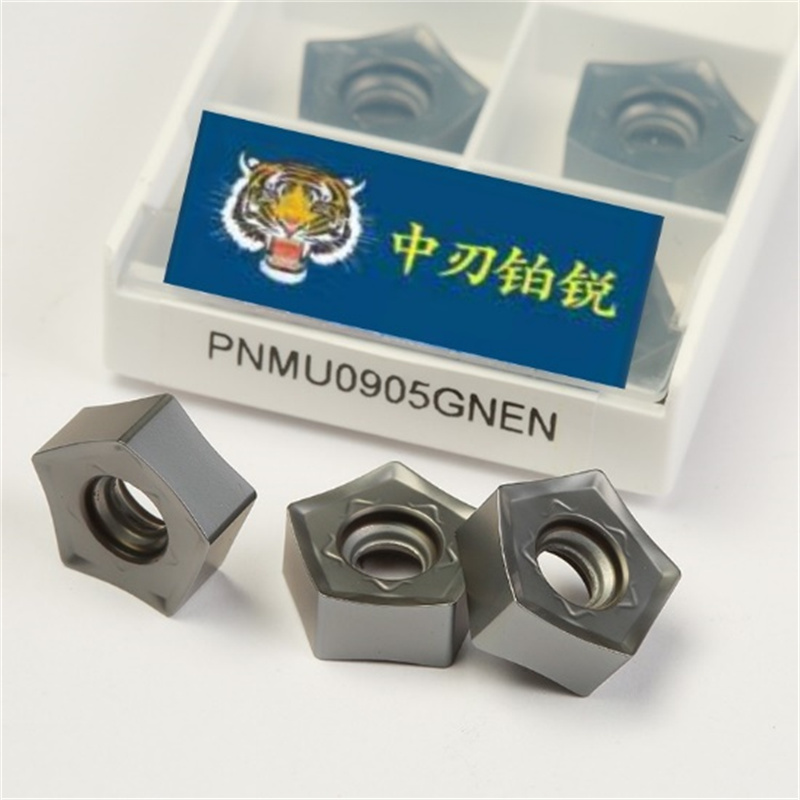

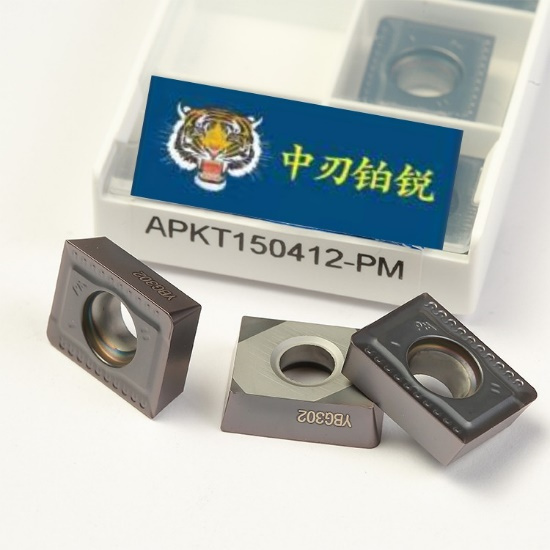

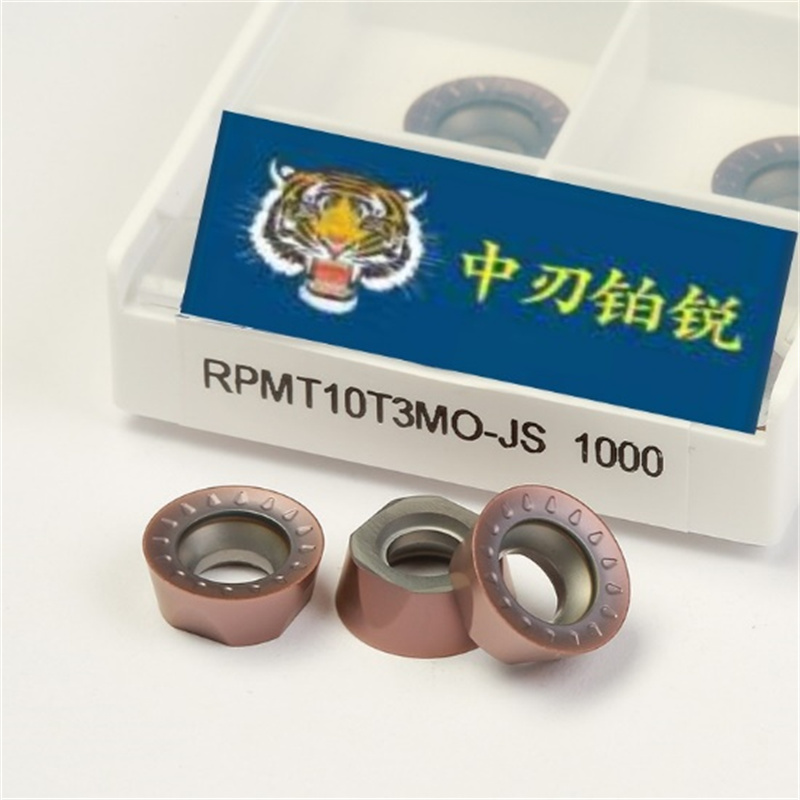

APMT1135 ni iy'urusyo rwa rutugu rwa kare, rutanga amasura abiri icyarimwe, bisaba guhuza urusyo rwa periferiya no gusya mu maso.Urutugu rwo mu rutugu rwibishushanyo bisanzwe rushobora gusya "ukuri", dogere 90 zintugu.Urusyo rwinshi rwo mu rutugu ni urusyo rusange, kandi rushobora gukoreshwa neza mugukora umwobo.Gusya ibitugu birashobora gukorwa hamwe nogusya ibitugu gakondo, urusyo rwanyuma, imashini ndende yo gusya, ibyuma byo gusya kuruhande hamwe no gusya mumaso nabyo birashobora gukoreshwa.

Porogaramu nyamukuru :

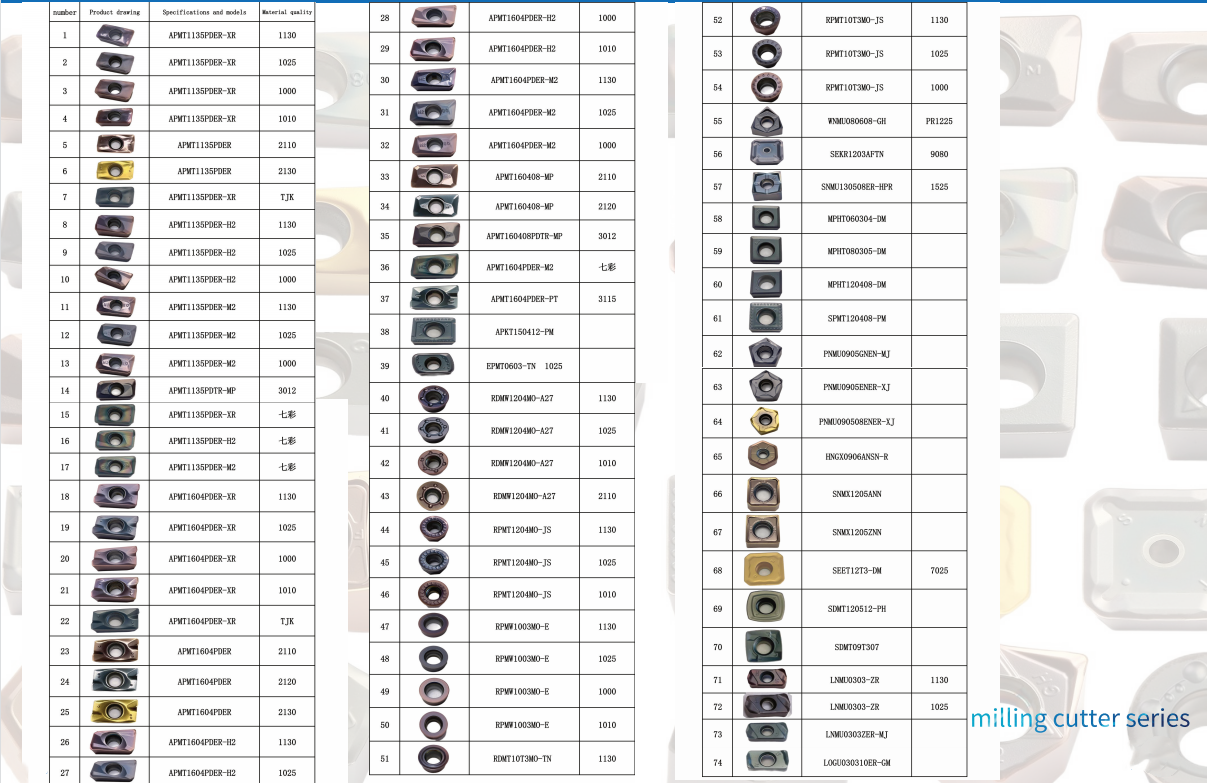

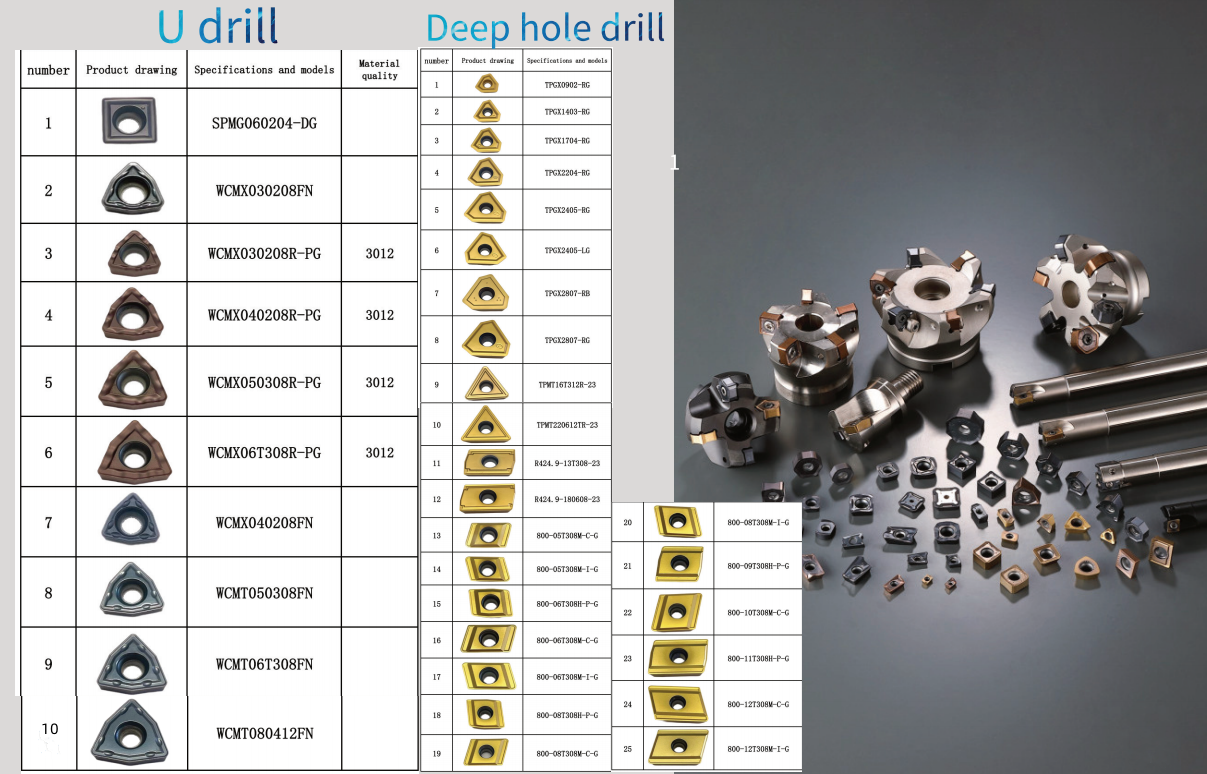

Mugutunganya ibyuma bya karubone, ibyuma, ibyuma bidafite ingese

Inganda zikoreshwa:

CNC ihinduranya no gusya ibikoresho bya tungsten carbide ibikoresho byinjizwamo bikoreshwa cyane muri: Inganda zikora amamodoka, inganda zikora ibicuruzwa, inganda zindege, inganda zingabo, inganda zitunganya cyane nibindi byinshi.

turashobora kubyara ubwoko butandukanye tungsten carbide ibikoresho byo gukata ushiramo ukurikije ibishushanyo bitandukanye byabigenewe.

turashobora gutanga ibisubizo byunganira muri rusange kumashanyarazi.

Ibikoresho byo gukora

QC Ibikoresho

Impamyabumenyi

Ibyiza

1. Byakemuwe neza byubaka akazi gakomeye nibindi bibazo byo gutunganya.

2. Gukata impande zose ni byiza kugenzura icyerekezo cya chip kandi ukabona ubuziranenge bwubuso.

3. Gukata gukabije, imbaraga nto zo gukata.

4. Gutunganya neza ubuziranenge bwubuso.

5. Igishushanyo kidasanzwe cya chip breaker kugirango ukomeze guca inkari kandi itekanye.

6. Kurwanya ingaruka nziza.

7. Igikoresho cyiza cyigihe cyubuzima.

Ibiranga

1.uburyo bwihariye bwo kuvura hamwe no gutwikira.

2.kureka gutunganya neza.

3. gutanga ifunguro rya mugitondo na serivisi nziza.

4. Ubwiza buhanitse hamwe nigiciro cyo gupiganwa.

5. Ikoreshwa cyane mu nganda zimashini zikora ibyuma

6. Ibisobanuro byuzuye, gusimburwa byoroshye, gukoresha rusange.