Ubwiza buhebuje APMT CNC yinjiza ubwoko bwo gusya APMT1604PDER-HT 1120 Isoko ritaziguye riva mubakora

Amakuru Yibanze

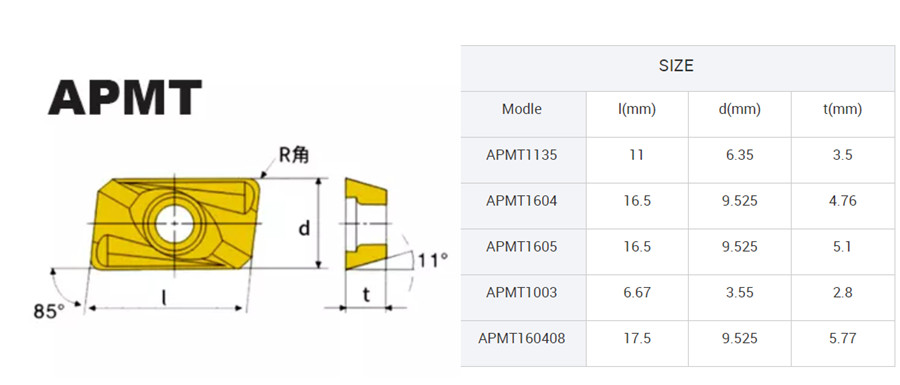

Carbide APMT PVD Gushyiramo ibisanzwe bikoreshwa mubisanzwe byerekana kwaduka kwaduka ibitugu birangira no gusya.Kwinjiza APMT hamwe nibisobanuro byuzuye IC, icyuma cyiza cya chip breaker.Bafite inkingi ikarishye kandi yubashywe hamwe na 11 ° yo gutabara.Bafite imyobo ya screw yaremewe kubahiriza ISO.Mubisanzwe, bireba nku mpande 2 zo gukata.Ariko, mubyukuri bafite impande 4 zo guca.mugihe zashyizwe kuri 90 ° zogusya zogusya kandi impande zombi zikaba zijimye, zirashobora gushyirwaho kuri 75 ° indangagaciro zogusya  hanyuma ugakomeza izindi porogaramu zisya hamwe nizindi mpande zombi.APMT izaba ihitamo ryiza kubakoresha amaherezo, kuva irashobora kuzamura umusaruro cyane.

Ibyiza

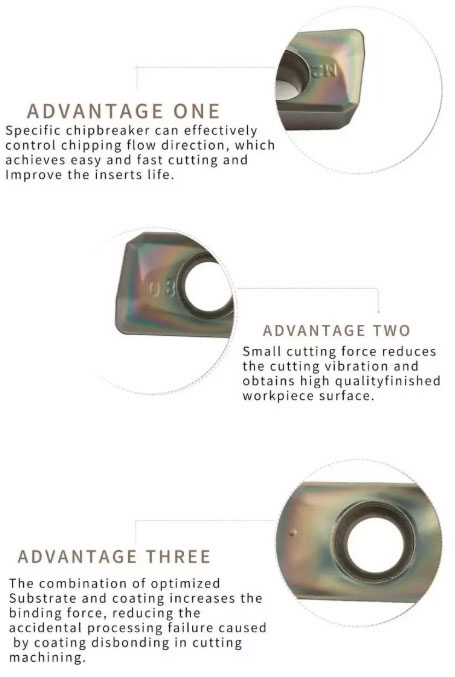

1. Kurwanya kwambara neza, imbaraga zunamye cyane, guhangana gukomeye, kurwanya ubushyuhe bwiza, gukomera no gukomera.

2. Kuramba kuramba kandi byoroshye guterana, nta gucamo cyangwa gukata

3. Ibisobanuro nukuri kubwoko bwa CNC bwinjiza ni kubahiriza byimazeyo ISO.

Ibiranga

1. Ubwiza bwo hejuru

2. Ingaruka nziza zikomeye no kwambara birwanya

3. Kuba isi yose

4. Gucunga neza sisitemu yo gucunga neza kugirango yemeze ubuziranenge buhoraho

5. Kurwanya kwambara neza, gukomera gukomeye, kunoza umusaruro.

6. Ubutaka bwuzuye kandi busukuye, ingaruka nziza yo gukata

7. Igipfundikizo cya PVD cyemeza ibikoresho birebire ubuzima.

Gusaba

Porogaramu nyamukuru:Mugutunganya ibyuma bya karubone, ibyuma, ibyuma bidafite ingese

Inganda zikoreshwa:CNC ihinduranya no gusya ibikoresho bya tungsten carbide ibikoresho byinjizwamo bikoreshwa cyane muri: Inganda zikora amamodoka, inganda zikora ibicuruzwa, inganda zindege, inganda zingabo, inganda zitunganya cyane nibindi byinshi.

turashobora kubyara ubwoko butandukanye tungsten carbide ibikoresho byo gukata ushiramo ukurikije ibishushanyo bitandukanye byabigenewe.

turashobora gutanga ibisubizo byunganira muri rusange kumashanyarazi.

Ibicuruzwa byihariye

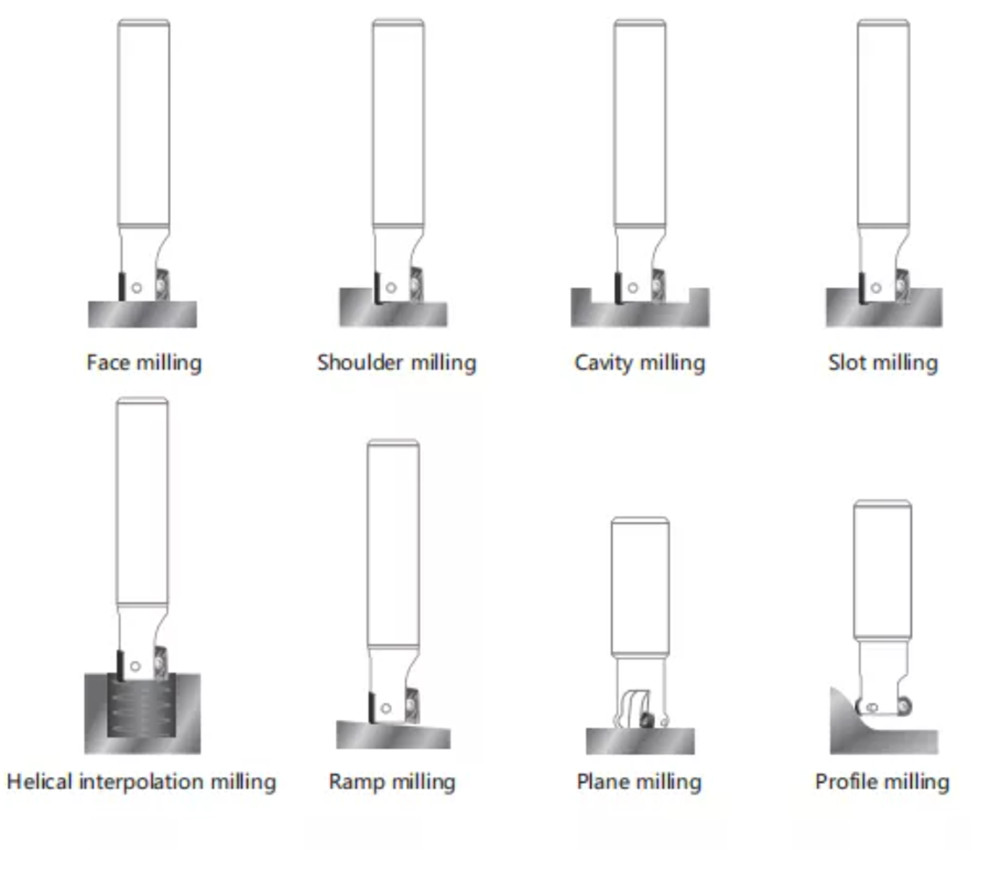

Waba ukeneye gusya muri rusange cyangwa gusya kuremereye kugirango usya mu maso, gusya ibitugu, gusya ahabigenewe, gusya umwirondoro, cyangwa gusya, cyangwa no gusya ibisabwa hejuru kugirango uburinganire bworoshye, injeniyeri wacu arashobora guhindura igishushanyo cyawe mugusya muminsi mike.

Kwerekana

Impamyabumenyi

Ibikoresho byo gukora

QC Ibikoresho